Functional Wheat Bread from Partially Substituted Margarine with Cow’s Femoral Bone Marrow: Influence on the Bread Indexes and Acceptability

Innocent Nwazulu Okwunodulu*, Rhoda Chidinma Chukwu, Anthony Nwankwo Ukom and Offor Maduebibisiwe

Published Date: 2025-03-28Innocent Nwazulu Okwunodulu*, Rhoda Chidinma Chukwu, Anthony Nwankwo Ukom and Offor Maduebibisiwe

Department of Food Science and Technology, Michael Okpara University of Agriculture, Umudike, Abia State, Nigeria

- *Corresponding Author:

- Innocent Nwazulu Okwunodulu

Department of Food Science and Technology, Michael Okpara University of Agriculture, Umudike, Abia State, Nigeria

E-mail:nncntokwu@yahoo.com

Received date: February 20, 2024, Manuscript No. IPJCND-24-18670; Editor assigned date: February 22, 2024, PreQC No. IPJCND-24-18670 (PQ); Reviewed date: March 07, 2024, QC No. IPJCND-24-18670; Revised date: March 21, 2025, Manuscript No. IPJCND-24-18670 (R); Published date: March 28, 2025, DOI: 10.36648/2472-1921.11.2.158

Citation: Okwunodulu IN, Chukwu RC, Ukom AN, Maduebibisiwe O (2025) Functional Wheat Bread from Partially Substituted Margarine with Cow’s Femoral Bone Marrow: Influence on the Bread Indexes and Acceptability. J Clin Nutr Diet Vol:11 No:2

Abstract

Background: This work understudied the influence of partial substitution of margarine with cow’s femoral bone marrow on wheat bread indexes and acceptability. High cost of margarine which results in high cost of bread beyond the reach of common man calls for substitution. Substituting with bone marrow which underlines backward integration of underutilized bone marrow that will reduces bread price, conserve foreign exchange for importing countries, produce novel bread and reduce butter consumption alongside its cardiovascular disorders becomes an inevitable option to explore.

Objectives: This work investigated the possibility of partial replacement of margarine with femoral cow’s bone marrow to produce novel wheat bread with some functional characteristics while saving foreign exchange for importing margarine.

Methods: Wheat breads were baked with wheat flour, same recipes and partial replacement of fat with bone marrow in the ratios of 80:20, 50:50 and 20:80, while 100% margarine and bone marrow breads samples served as controls. The ingredients were first measured, mixed and kneaded with water and wheat flour into dough. Each dough sample was separately rolled, cut (equal sizes), panned, proofed for 30 min, baked at 180°C for 35 min in the oven, cooled, wrapped and refrigerated for analysis.

Results: With increase in bone marrow substitution levels, fat (14.37-16.67%), ash (3.00-3.28%), protein (10.14-13.31%), energy value (408.63-425.49% kcal/g), calcium (45.25-47.05 mg/g) and iron (1.13-1.21 mg/g) increased. Thiamine (0.33-0.50 mg/g), B2 riboflavin (0.28-0.41 mg/g) and vitamin E (0.33-0.44 mg/g) also increased. Oven spring (0.55-0.60), loaf weight (345.60-349.88 g), loaf volume (537.29-558.88 cm3), specific volume (1.56-1.60 cm3/g) and crumb/crust colour (3.25-3.64) increased. Moisture content (12.66-11.06%), fibre (0.17-0.14%), carbohydrate (59.70-55.56%), sodium (4.31-3.80 mg/g), magnesium (12.65-11.30 mg/g), potassium (10.60-9.33 mg/g), B3, niacin, (0.17-0.14 mg/g) and vitamin A (1.70-1.54 mg/g) decreased. Maximum acceptability of 7.70 was obtained from 80% margarine and 20% bone marrow, while the 50 margarine: 50 bone marrow substituted bread was the least (7.15).

Conclusion: Substituting fat with bone marrow produced nutritious and acceptable breads with lower sodium content.

Keywords

Wheat bread; Margarine substitution; Bone marrow; Bread indexes; Acceptability

Introduction

Bread is an important staple food highly relished on in both developing and developed countries in many homes, restaurants and hotels among every socioeconomic class of all ages and sexes. Bread is a fermented confectionary baked mainly with wheat flour, yeast, water, sugar, salt, shortening and other ingredients according to choice. The processes involve mixing, kneading, proofing, shaping and baking. When formulating the ingredients, health benefits, fat replacement and ingredient interactions are factored in. Depending on the nutritional composition of the wheat flour bread is an excellent source of complex carbohydrates and micronutrient essential for human health [1].

Wheat flour is a source of vitamins (B vitamins), dietary fiber phytochemicals and gluten forming proteins, gliadins and glutenins. The unique properties of the wheat gluten make it unique in bread making [2]. When gluten is mixed with water, it forms a matrix that provides the dough structure needed for the development of desirable high volume and soft texture of bread.

Wheat gluten contains alcohol soluble glaidin and insoluble glutenin. Gliadin contains intra-molecular disulfide bonds which breaking causes unfolding of the protein molecules. Gliadin is responsible for the cohesive property of gluten while glutenin is multi-chained proteins, mainly polymerized by disulfide bonds and predominantly responsible for the elastic properties and extensibility of dough. Their relative proportions in gluten affect the dough rheological properties and viscoelastic (viscous and elastic characteristics) [3]. Therefore, correct balance of viscoelastic properties is very important to a successful sheeting process.

Fats are very vital raw materials for several food products like confectionery. In bread baking, fat improves gas retention in the dough which in turn increases loaf volume, softness and desirable texture. Fat enhances the caloric value and fat soluble vitamins of bread. Fat also retards drying out, aids the expansion of gluten network and tend to “shorten” the gluten strands in bread flour. Fat replacers are ingredients used to provide some or all of the functions of fat with fewer calories than fat [4].

Consumption of animal by-products has gained tremendous growth over the last decade due to their potentials to combat food insecurity in many countries. Bone Marrow (BM), an animal by-product is a spongy tissue mostly found in the femur bone centers. It is divided into red marrow (Medulla ossiumrubra) consisting mainly of hematopoietic tissue that develops into red and white blood cells as well as platelets. And yellow marrow (Medulla ossiumflava) consisting mainly of fat cells [5,6]. The BM can be found in almost any bone that holds cancellous (spongy) tissue and a source of micronutrient (vitamin A, vitamin E, calcium and iron). Cancellous tissues supports joint function, decreases inflammation and contains several health promoting compounds among others. The BM of domesticated animals are commonly used for culinary purposes, bone broth and baking among others. The BM generally contains 70% fat. Adeyeye reported 98.20% to 98.70% crude fat, 25.40% to 43.30% saturated fatty acids, 41.50% to 45.50% Monounsaturated Fatty Acids (MUFA), and 15.20% to 29.10% total Polyunsaturated Fatty Acids (PUFA) for ram and bull BM. High cost and availability of butter prompted its partial substitution with BM also to substitute trans-fat or saturated fat. It will also reduce overreliance on margarine which contains considerable amounts of saturated fatty acids and fatty acid trans-isomers which frequent consumption results in cardiovascular disorders. The main objective of this study is to evaluate the influence of margarine substitution with BM in bread indexes and acceptability.

Materials and Methods

Materials

Wheat grains (Figure 1a), femur bones (Figure 1b) and ingredients used in this study were procured from Ubani main market, Umuahia, Abia state.

Sample preparation

Production of wheat flour: The method described by Ndife et al., was used in the production of wheat flour. Wheat grains were sorted, washed (in water), drained, dried (oven at 60°C for 8 h), milled (attrition mill) and sieved (2 mm mesh screen) to obtain whole wheat flour. The flour (Figure 1c) was stored in an airtight polyethylene for further use.

Bone marrow extraction

The femur bones procured were thoroughly washed with water by the butcher, bisected manually with stainless steel cutlass, the bone marrow (Figure 1d) extracted manually, packaged in an airtight polyethylene and stored in refrigerator for baking.

Figure 1: (a) Wheat grains; (b) Femur bones; (c) Wheat flour; (d) Bone marrow.

Production of bread

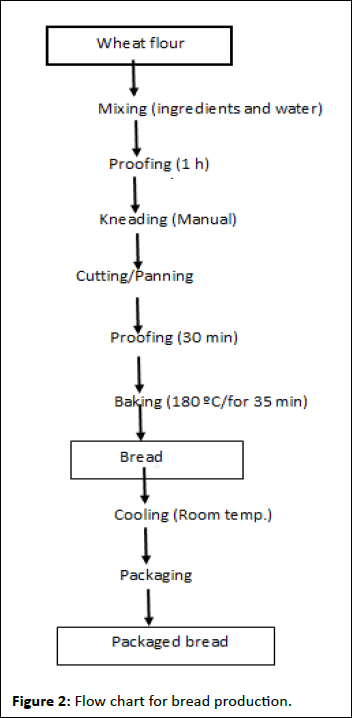

The wheat flour was divided into five portions and separately mixed according to the formulation (Table 1) to obtain the dough samples that were left to proof for 1 h. Thereafter, they were manually and separately kneaded, cut (equal sizes), panned, proofed (30 min) and baked at 180°C for 35 min to obtain the breads. The breads were then brought out of the oven, allowed to cool to room temperature and packaged thereafter in an airtight polyethylene for analyses (Figure 2).

| Ingredients | Bread samples | ||||

| A | B | C | D | E | |

| Wheat flour (g) | 500 | 500 | 500 | 500 | 500 |

| Water (ml) | 300 | 300 | 300 | 300 | 300 |

| Yeast (g) | 10 | 10 | 10 | 10 | 10 |

| Salt (g) | 6 | 6 | 6 | 6 | 6 |

| Margarine (g) | 30 | 24 | 15 | 6 | 0 |

| Bone marrow (g) | 0 | 6 | 15 | 24 | 30 |

| Improver (g) | 5 | 5 | 5 | 5 | 5 |

| Calcium propionate (g) | 4 | 4 | 4 | 4 | 4 |

Table 1: Recipes for dough formulation.

Figure 2: Flow chart for bread production.

Analyses

Proximate composition of the bread samples: Moisture, ash, crude fiber, fat and crude protein were determined as described by Onwuka. Carbohydrate content was determined by difference and energy by calculation.

Vitamin content of the breads: Pro-vitamin A, thiamin, riboflavin, vitamin E and niacin were determined by the protocol of Onwuka.

Mineral content of breads: Iron was determined by AOAC method while calcium, potassium and sodium were by Onwuka method.

Physical properties of the bread

The bread weights were determined by Dabels, et al., volumes were by measuring the Length (L), Height (H) and Breath (B), and multiply them according to Eke-Ejiofor, et al. Specific volumes were calculated by dividing the volume with the weight of the bread while oven spring was by subtracting dough height from that of the loaf according to Dabels, et al.

Colour intensity

Modified method of Okwunodulu, et al., was used. One gram of the bread samples was dissolved in fifty milliliters of distilled water. The filtrate was used to determine the colour intensity of the bread by measuring the absorbance with UV-VIS spectrophotometer at 550 nm absorbance. Colour intensity of the bread samples was determined as follows:

(10 × A × F)/(Sample weight (g))

Where,

F=Dilution factor

A=Absorbance

10=Concentration of solution

Sensory evaluation of the breads

The method described by Iwe was used with untrained panelists (n=30) randomly selected from students of Department of Food Science and Technology, Michael Okpara University of Agriculture, Umudike, Abia State. The bread slices were presented separately to each panelist (coded) in identical plates inside a well-lighted room with a bottle of water each. They were instructed to rinse their mouths before and after tasting each sample. Using the 9 point–Hedonic scale, the panelists were instructed to score the bread samples for appearance, taste, texture, aroma and overall acceptability. Where 9 is like extremely, 1 is disliked extremely and 5 is neither like nor dislike [7].

Statistical analysis

Data obtained were subjected to Analysis of Variance (ANOVA) of a Completely Randomized Design (CRD) using Statistical Product of Service Solution version 22.0 for personal computer. Means were separated using Duncan multiple range test at 95% confidence level (p<0.05).

Results and Discussion

Proximate composition

Moisture Content (MC): Proximate results presented in Table 2 indicated significant (p<0.05) MC decrease (12.66-11.06%) with increase in Bone Marrow Substitution Levels (BMSL) lower than the control (12.82%). The variation could be attributed to the higher MC of margarine which is water in oil emulsion unlike BM, a natural fat. In line with this, Rajah had reported a minimum of 80% fat with maximum of 16% water for margarine. Therefore, the decrease could in part be linked to MC reduction effect of the BMSL in the loaves. The variation is also justified by the significant (p<0.05) higher MC of the control (12.82%) than 100% BM bread sample (10.31%). Similar MC decrease was obtained by Makinde and Makanjuola, for bread baked with margarine and coconut blend. Although, high moisture content is associated with mold growth and short shelf life of bread as it encourages microbial proliferation conversely, it will make the loaves softer, delays staling, easy to masticate and swallow. The Bone Marrow Substituted Breads (BMSBs) therefore may likely have harder texture than the control which is expected to have prolonged staling with little or no difference in swallowing between them. The Bone Marrow (BM) fat which is predominantly solid at room temperature may not have mixed properly during kneading to properly coat water molecules and prevent their escape. The MC values of BMSBs (11.06-12.66%) obtained in this study were lower than 28.20-28.42% reported by Makinde and Makanjuola and 31.83% to 34.48% obtained by Nwanekezi and Umeonuorah for bread made with bullet pear fruit oil. The results correlated with 11.13 to 14.60% reported by Hussein, et al., for cookies produced by partial substitution of margarine with avocado pear. The variations could be due to the differences in the materials, quantity of water used and degree of oil saturation.

| Samples | Moisture | Fat | Fibre | Ash | Protein | CHO | Energy value (kcal/g) |

| A | 12.82a ± 0.02 | 11.05e ± 0.02 | 0.20a ± 0.01 | 2.95d ± 0.01 | 9.23e ± 0.01 | 63.77a ± 0.05 | 391.39e ± 0.05 |

| B | 12.66b ± 0.57 | 14.37d ± 0.02 | 0.14cd ± 0.01 | 3.00d ± 0.03 | 10.14d ± 0.01 | 59.70b ± 0.08 | 408.63d ± 0.50 |

| C | 12.24c ± 0.01 | 16.42c ± 0.03 | 0.17ab ± 0.01 | 3.16c ± 0.01 | 12.44c ± 0.01 | 55.58c ± 0.06 | 419.82c ± 0.08 |

| D | 11.06d ± 0.02 | 16.67b ± 0.03 | 0.14cd ± 0.01 | 3.28b ± 0.04 | 13.31b ± 0.01 | 55.56c ± 0.02 | 425.49b ± 0.40 |

| E | 10.31e ± 0.06 | 16.77a ± 0.14 | 0.17bc ± 0.01 | 3.48a ± 0.03 | 13.84a ± 0.23 | 55.44c ± 0.11 | 428.53a ± 0.27 |

| Note: Values are means of triplicate determination ± standard deviation. Values in the same column with different superscript are significantly (p<0.05) different. A=Bread made with 100% margarine (control). B=Bread made with 80% margarine and 20% bone marrow. C=Bread made with 50% margarine and 50% bone marrow. D=Bread made with 20% margarine and 80% bone marrow. E=Bread made with 100% bone marrow | |||||||

Table 2: Effects of bone marrow substitution on the proximate composition and energy values of bread samples (%).

Fat

Significant (p<0.05) BMSBs increased (14.37-16.77%) with increase in BMSL more than the control (11.05%) aligned with the report of Meyerholtz, et al., that BM contains basically fat (>80%) and Conjugated Linoleic Acid (CLA) that decreases inflammation and enhances immune function. Similar increase was reported by Makinde and Makanjuola. As fat is a good source of fat soluble vitamins, essential fatty acids, enhances flavor, an energy substrate, retards drying out and aids in swallowing, the BMSBs may likely be more flavourful, nutritious, energy dense and slow to retard than the control, depending on the level of BMSL. Therefore, BM is preferred in bread baking as higher oil affects the shelf stability depending on the degree of saturation, packaging and preservation technique. The fat values in this study were higher than 8.14-8.60% and 3.62-4.62% reported by Nwanekezi, et al. and Makinde, et al. and respectively for breads from fat substituted with bullet pear fruit oil and coconut oil. May be the fat content BM is higher than the oils or the levels of oil used were low.

Fiber

Fibre is none digestible carbohydrate endowed with a lot of health benefits which significant (p<0.05) decrease (0.17-0.14%) in BMSBs lower than the control (0.20%) is not encouraged with increase in BMSL. This could explain the higher fibre content of the control than the 100% BM bread due to dilution factor. The decrease could be associated to the proportional fat increase due to BMSL Lower fiber values of BMSBs are suitable to infants and could help to reduce incidence of diabetics and high blood pressure among the vulnerable elderly over time. They will also offer good intestinal health. Fibre levels of the BMSBs in this study (0.14-0.17%) were lower than 0.18%-0.27% reported by Nwanekezi and Umeonuorah for bread baked with bullet oil and similar fibre decreasing trend (1.45-1.29%) by Makinde and Makanjuola. Therefore, consumption of fibrous foods is highly beneficial to human health.

Ash

Ash depicts the level of mineral content of food materials. Significant (p<0.05) ash content increase in BMSBs (3.00-3.48%) with BMSL increase than the control 2.95% which established higher mineral content is welcomed. The health benefits associated with minerals is also assured. The ash values of BMSBs in this study is higher than 2.67-3.01% reported by Othman, et al., for avocado puree replaced fat in low fat muffins. Similar fibre increase was reported by Makinde and Makanjuola. Probably, BM must have contained more minerals than avocado puree and coconut oil.

Protein

The protein content of BMSBs progressively improved (10.14-13.31%) significantly (p<0.05) with increase in BMSL. Significant (p<0.05) higher protein content of 100% BM bread sample (13.84) than the control (9.23%) could attest that. Also, BM is a better protein source than margarine as animals are better protein sources than plants. Most importantly, BM contains adiponectin, a type of protein hormone that has insulin sensitizing, anti-inflammatory and cardio-protective roles. Furthermore, BM is rich in collagen, the most abundant protein in the body that promotes skin health and reduces joint pain. The BM also contains glycine a type of protein that possesses a powerful anti-inflammatory property. Therefore, BM must have contained more protein than wheat flour and margarine. The values in this study were higher than 7.57-7.58% reported by Nwanekezi and Umeonuorah and similar protein improvement (9.21-9.23%) of Makinde and Makanjuola.

Carbohydrate

The carbohydrate content of the BMSBs decreased (59.70-55.56%) significantly (p<0.05) as from 50% BMSL which never differ from the rest samples. The entire decrease was lower than the control (63.77%). Absence of carbohydrate in BM could be implicated. Besides, interactions of fat with carbohydrates must have contributed as evidenced in the increasing trend of fat with BM increasing substitution. The BM contains basically fat with little carbohydrate since it is from animal source. Similar decrease was advanced by Makinde and Makanjuola which results (55.86-55.63%) were lower than the values obtained in this study. The carbohydrate values in this study were within 58.86-62.22% reported by Hussein, et al., for cookies produced by partial substitution of margarine with avocado pear.

Energy value

The energy value of the BMSBs increased (408.63 to 425.49 kcal/g) significantly (p<0.05) with increase in BMSL more than the control (391.39 kcal/g). Increasing fat and protein values of BMSBs with BMSL than the control which are major energy substrates could substantiate the increase. Therefore, BMSBs is a better energy source needed by the body to carry out body activities and work than the wheat bread. The energy values in this study were higher than 286.39 to 305.16 kcal/100g calories reported by Nwanekezi and Umeonuorah and similar increasing values (295.29-298.86 kcal/g) of Makinde and Makanjuola.

Vitamin content

Vitamin A: Vitamin A is fat soluble and aids in sight which deficiency results in night blindness and age-related problems. The vitamin results (Table 3) established a desiring vitamin A improvement (1.54-1.70 mg/100g) with BMSL increase in all the BMSBs despite their lower values than the control (1.83 mg/100 g). The BM is a better source of vitamin A hence the increase. Higher value of the control and the decrease in vitamin A after the peak (1.70 mg/100 g) at 50% BMS level could stem from the fortification of margarine with vitamin A during production to improve its nutritional value because animal products are better source. The values in this study are lower than 1.75 to 1.97 mg/100 g reported by Nwanekezi and Umeonuorah [8]. Other ingredients in the formulation may have contributed as well.

| Samples | Vitamin A | Vitamin B1 | Vitamin B2 | Vitamin B3 | Vitamin E |

| A | 1.83a ± 0.0 | 0.28d ± 0.02 | 0.16d ± 0.01 | 1.30a ± 0.14 | 0.28d ± 0.01 |

| B | 1.54c ± 0.01 | 0.33c ± 0.01 | 0.28c ± 0.01 | 0.14b ± 0.01 | 0.33c ± 0.01 |

| C | 1.70b ± 0.01 | 0.56a ± 0.02 | 0.41a ± 0.01 | 0.17b ± 0.01 | 0.44a ± 0.01 |

| D | 1.56c ± 0.01 | 0.50b ± 0.01 | 0.37b ± 0.01 | 0.16b ± 0.01 | 0.39b ± 0.01 |

| E | 1.56c ± 0.01 | 0.51b ± 0.01 | 0.38ab ± 0.01 | 0.18b ± 0.01 | 0.37b ± 0.01 |

| Note: Values are means of triplicate determination ± standard deviation. Values in the same column with different superscript are significantly (p<0.05) different. A=Bread made with 100% margarine (control). B=Bread made with 80% margarine and 20% bone marrow. C=Bread made with 50% margarine and 50% bone marrow. D=Bread made with 20% margarine and 80% bone marrow. E=Bread made with 100% bone marrow. | |||||

Table 3: Effects of bone marrow substitution on the vitamin content of the bread samples (mg/100 g).

Vitamin B1 (Thiamine): The same improvement trend of vitamin A was observed in all the BMSBs here (0.33-0.50 mg/ 100g), but more than the control (0.28 mg, 100g) with increase in BMSL. Significant (p<0.05) higher vitamin B1 content of 100% BM bread sample (0.51 mg/100g) than the control must have made the difference. It also projected BM as a better source. Also, B1 is water soluble that peaked (0.56 mg/100g) also at 50% BMSL as in vitamin A indicating 50% as peak BMSL.

Vitamin B2 (Riboflavin): Just like in vitamins A and B1, B2 of BMSBs increased (0.28-0.41 mg/100 g) with maximum value at 50% BMSL and decreased to 0.37 mg/100 g with further increasing BMSL. The improvements were significantly (p<0.05) higher than the control (0.16 mg/100 g) and could be attributed in part to higher B1 value of 100% BM bread (0.38 mg/100 g) than the control. The enhancement aligned with the report of Buehler that riboflavin is mostly found in animal products. Vitamin B2 plays a vital role in maintaining the body’s energy supply by converting carbohydrates into Adenosine Triphosphate (ATP). The BMSDs could be good active infants, elderly and recovering patients.

Vitamin B3 (Niacin): The vitamin B3 values of the BMSBs were enhanced (0.14-0.17 mg/100 g) without significant (p>0.05) variation as BMSL increased. The slight enhancement peaked (0.17 mg/100 g) at 50% BMS level and decreased (0.16 mg/100 g) thereafter lower than the control (0.30 mg/100 g). Lower value of 100% BM bread (0.18 mg/100 g) than the control as in vitamin A could explain the variations. Maximization of B3 (0.17 mg/100 g) is also at 50% BMS level.

Vitamin E: There was significant (p<0.05) higher vitamin E content of 100% BM bread (0.37 mg/100 g) than the control (1.30 mg/100 g). This connotes significant (p<0.05) vitamin E increase of all the BMSBs (0.33-0.44 mg/100 g) more than the control (0.28 mg/100 g) with increase in BMSL. The BM is a source of vitamin E source. Maximum improvement (0.44 mg/100 g) was observed at 50% BMSL as in other vitamins. The improvement could be attributed to the appreciable amount of α-tocopherol found in animals which has the highest biological activity and the most abundant form of vitamin E. Also, vitamin E is fat soluble and an anti-oxidant that helps to protect cells from the damage caused by free radicals and enhances fertility. The improvement is a welcome development liable to improve the anti-oxidant properties of the entire BMSBs for the benefit of the elderly and recuperating patients that consume them.

Mineral composition

Sodium: Mineral results of Table 4 revealed significant (p<0.05) sodium decrease of BMSBs (4.31-3.80 mg/100 g) lower than the control (5.31 mg/100 g) with increase in BMSL. The decrease could in part be associated with the significant (p<0.05) higher sodium content of the control (5.31 mg/100 g) than 100% BM bread (3.64 mg/100 g). Also, high sodium chloride used in margarine production may have contributed as well. Margarine is a popular high sodium product that is used in many culinary preparations and therefore an important contributor to sodium intake. However, as high sodium content is associated with an increased risk of hypertension, development of cardiovascular disease, osteoporosis and kidney stone incident, demand for low-sodium product has increased. Therefore, sodium decrease in BMSBs is a better option in this regard. The sodium levels of BMSBs obtained in this study is within 1.89-8.56 mg/100 g reported by Ndife, et al., for enriched cookies from whole wheat and full fat soya flour blends, but lower than 2410.70-2440.03 mg/kg reported by Makinde and Makanjuola. Therefore low sodium bread is possible with bone marrow substitution of margarine which will mitigate sodium content and prevent or control high blood pressure. Furthermore, sodium: potassium ratios (0.38-0.47) of the breads were within the recommended reference value of <1.0 with the control having the highest value (0.47) [9]. The decreasing trend of sodium: potassium ratio with BM substitution increase traceable to reasonable higher potassium content in relation to sodium also corroborated the benefit of lowering/preventing or controlling the risk of high blood pressure for those prone to that Perez and Chang.

| Samples | Sodium | Iron | Calcium | Magnesium | Potassium |

| A | 5.31a ± 0.01 | 0.84d ± 0.02 | 38.95e ± 0.35 | 14.13a ± 0.00 | 11.25a ± 0.70 |

| B | 4.31b ± 0.01 | 1.13c ± 0.01 | 41.65d ± 0.21 | 12.65b ± 0.07 | 10.60b ± 0.14 |

| C | 4.08c ± 0.01 | 1.16c ± 0.02 | 45.25c ± 0.07 | 11.75c ± 0.07 | 10.00c ± 0.00 |

| D | 3.80d ± 0.01 | 1.21b ± 0.01 | 47.05b ± 0.07 | 11.50d ± 0.14 | 9.54d ± 0.01 |

| E | 3.64e ± 0.01 | 1.27a ± 0.01 | 47.75a ± 0.07 | 10.75e ± 0.07 | 9.53e ± 0.01 |

| Note: Values are means of triplicate determination ± standard deviation. Values in the same column with different superscript are significantly (p<0.05) different. A=Bread made with 100% margarine (control). B=Bread made with 80% margarine and 20% bone marrow. C=Bread made with 50% margarine and 50% bone marrow. D=Bread made with 20% margarine and 80% bone marrow. E=Bread made with 100% bone marrow. | |||||

Table 4: Effects of bone marrow substitution on the mineral content of the bread samples (mg/100g).

Iron: The iron content of the BMSBs improved (1.13-1.21 mg/100 g) significantly (p<0.05) with increase in BMSL higher than the control (0.84 mg/100 g). The improvement is traceable to higher iron content of 100% BM bread (1.27 mg/100 g) than the control. Again, heme-iron is only found in animal with higher bioavailability and better absorption than non-heme-iron from plant. Besides, BM is a source of iron. Therefore, BMSBs will have a better health benefit than margarine baked breads beneficial to the consumers. Iron primarily synergizes with protein and copper to produce blood cells that transport oxygen to all tissue parts to maintain all life functions. It is a component of some protein and enzyme that aids in metabolism. The BMSBs could be of benefit to elderly, sick and growing infants despite their lower values than 1.76-4.01 mg/100g reported by Nwanekezi and Umeonuorah, 70.56-82.29 mg/kg by Makinde and Makanjuola and 2.10 to 3.19 mg/100 g by Ndife, et al.

Calcium: Calcium is the most abundant mineral in the BMSBs which aligned with the literature assertion that calcium is the most abundant mineral in the body. Calcium content of the BMSBs also improved (41.65-47.05 mg/100 g) linearly in response to increase in BMSL. The improvement was significantly (p<0.05) higher than the control (38.95 mg/100 g) and could be due to appreciable higher calcium content of 100% BM bread than the control. The BM is also a source of calcium. Calcium synergizes with phosphorus to enhance muscle contraction, building strong bones and teeth, regulate heart beat and fluid balance within cells. The improvement will contribute in alleviating osteoporosis in elderly, rickets in infants and good for recovering patients. The calcium values of BMSBs in this study were higher than 16.34 to 21.02 mg/100 g reported by Nwanekezi and Umeonuorah.

Magnesium: Like in sodium, the magnesium content of BMSBs decreased (12.65-11.50 mg/100 g) lower (p<0.05) than the control (14.13 mg/100 g) with increase in BMSL. The difference could be attributed to higher magnesium content of control than 100% BM bread (10.75 mg/100 g). The decrease indicated peak value of BMSBs is at 20% BMSL. This is in line with the report that magnesium is found abundantly in plants than in animals. The decrease is not desired unless made up by other diets. The magnesium levels of BMSBs in this study were lower than similar decreasing trend (321.15-311.49 mg/kg) reported by Makinde and Makanjuola. Magnesium plays a vital role in energy production, bone development, regulation of muscular contraction, insulin metabolism and reduces high blood pressure. The decrease is not desired in this regard. Also, the values were lower than 62.46-65.28 mg/100g reported by Nwanekezi and Umeonuorah.

Potassium: Potassium content of BMSBs decreased as in magnesium with increase in BMSL probably due to higher potassium in plants from where margarine was produced than animal sources. Potassium plays an important role in improving bone health and reduces osteoporosis, a condition in which the bones becomes weak and are easily broken. The decrease is also not encouraged. The values (9.54-10.60 mg/100 g) obtained in this study were lower than 1269.80-1546.50 mg/kg reported by Makinde and Makanjuola.

Physical characteristics

Oven Spring (OS): This is sudden bread volume rise due to sudden high temperature exposure of the dough in the oven that attenuated yeast activity before killing it. The results of physical characteristics of the breads (Table 5) recognized none significant (p>0.05) OS variations of the BMSBs (0.60-0.55 g) except in the equal blended bread (50% margarine-BM) that is lower (p<0.05) compared to others. Despite significant (p<0.05) higher OS (0.57 g) value of the control than 100% BM bread (0.52 g), least value (0.55 g) of equal blended bread sample could stem from the interactive effect of the blending on OS. Same (0.60 g) and higher OS values of samples B (80% margarine and 30% BM) and D (20% margarine and 80% BM) could be associated with their higher fat content that increases volume. This therefore underlined positive correlations of 20% BM and 80% margarine substitution levels with peak OS. The two blends may have contributed higher fat content that coated the dough surface and prevented gas escape thereby increased the OS unlike the equal blends. The increase is desired as it will enhance acceptability. The values in this study were higher than 0.40-0.41 g reported by Makinde and Makanjuola for bread produced with coconut oil. The variations could depend on the quantity and proportions of glaidin and glutenin in the flour and the fat content of coconut oil used.

| Samples | Oven spring (g) | Loaf weight (g) | Loaf volume (cm3) | Specific volume (cm3/g) | Crumb and crust colour |

| A | 0.57abc ± 0.01 | 344.58b ± 0.71 | 531.68d ± 2.09 | 1.55cd ± 0.01 | 3.23d ± 0.01 |

| B | 0.60a ± 0.28 | 349.88a ± 0.32 | 558.88a ± 0.05 | 1.60a ± 0.00 | 3.25d ± 0.01 |

| C | 0.55bc ± 0.01 | 345.60b ± 0.57 | 537.29c ± 0.54 | 1.56bc ± 0.01 | 3.64a ± 0.02 |

| D | 0.60a ± 0.02 | 347.03ab ± 2.46 | 542.14b ± 1.46 | 1.57b ± 0.01 | 3.41c ± 0.01 |

| E | 0.52c ± 0.02 | 325.28c ± 1.24 | 501.40e ± 1.56 | 1.54d ± 0.00 | 3.52b ± 0.01 |

| Note: Values are means of triplicate determination ± standard deviation. Values in the same column with different superscript are significantly (p<0.05) different. A=Bread made with 100% margarine (control). B=Bread made with 80% margarine and 20% bone marrow. C=Bread made with 50% margarine and 50% bone marrow. D=Bread made with 20% margarine and 80% bone marrow. E=Bread made with 100% bone marrow. | |||||

Table 5: Effects of bone marrow on the physical properties of the bread samples.

Loaf weight (LW): The LW of the BMSBs significantly (p<0.05) decreased (349.88-347.03 g) in response to BMSL increase. The decrease could be associated with uniform coating of fermentable components of the dough by the margarine oil thereby prevented yeast access to them and subsequence loss of dough elastic and extensibility properties that may likely lead to carbon dioxide loss. Also, Manzocco, et al., had reported volume increase with higher fat than weight. Significant (p<0.05) higher LW of the control (344.58 g) than 100% BM bread (325.03 g) could be a factor too. Despite the decrease, it is worthy to note that LW of all the BMSBs were higher than the control with peak value at 80% margarine and 20% BM blend while least value was at equal blended bread. May be the equal blending of margarine and BM contributed more fat. These may associate BM with higher melting point to liquefy and coat the fermentable components of the dough. The LW increase of BMSBs compared to the control is desired as consumers often times match weighted with volume in their choice for breads. The BM could be a better choice for short breads and cakes. The values obtained in this study were higher than 319.40-328.33 g reported by Nwanekezi and Umeonuorah and 232.10-236.40 g by Makinde and Makanjuola. The ratio of saturated and unsaturated fatty acids component of the bullet pear oil may be implicated in the variation.

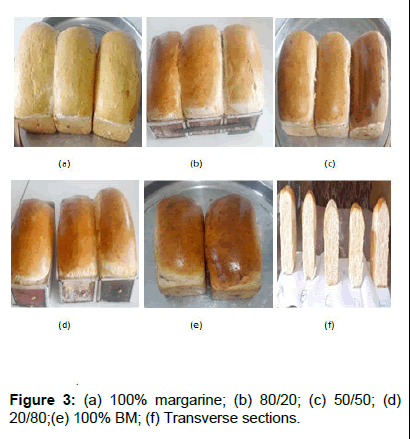

Loaf Volume (LV): The LV results from trapping of carbon dioxide produced by yeast during dough fermentation by the wheat flour gluten network. During baking, the high temperature coagulates the gluten structure and the bread becomes rigid without collapsing. The LV decides size, softness, desirable texture and attracts, but may or may not be the primary basis of acceptability. The same decreasing trend results of LW were observed here with same LV peak at 80% margarine and 20% BM. Therefore, 20% BMSL becomes the peak level for maximum carbon dioxide retention in the dough Manzocco, et al. Therefore, maximum LV is achievable at not more than 20% BMSL. The decreasing trend established here with increase in BMSL could be likened to decreasing coating of the disulfide bonds of the gluten components, glaidin and glutenin, of the dough by BM fat. The equal blending may have had more coating efficiency; hence the least LV among the BMSBs. Decreasing LV could also be substantiated by the increasing crust formation (Figures 3 b-e) that restricts dough expansion. The LV of the entire samples (537.29-558.88 cm3) in this study is higher than similar decreasing results (611.45-605.76 cm3) reported by Makinde and Makanjuola.

Specific Volume (SV): Same LW and LV trending results were observed here. The SV decreasing trend (1.60-1.54 cm3/g) in response to BMSL increase also peaked (1.60 cm3/g) at 80% margarine and 20% BM blend. While 50:50 blends had the least (1.56 cm3/g). The decrease may be ascribed to the significant (p<0.05) higher SV of the control than 100% BM bread. Also the decreasing trend of LW and LV could be a factor too. The values obtained in this study were lower than similar decreasing trend (2.64-2.56 cm3/g) reported by Makinde and Makanjuola. The variations in LW and LV may be from the ingredients used.

Crumb and Crust Colour (CCC): The CCC of the BMSBs increased (Figures 3 b-e) from 3.25-3.64 significantly (p<0.05) with increase in BMSL. The variation could be as a reflection of significant (p<0.05) higher value (3.52) of 100% BM bread sample (Figure 3e) than 3.23 from the control (Figure 3a). Higher CCC (3.64) of 50:50 BMSB than the entire samples indicated that BM should not exceed 50% for maximum CCC. This peak value substantiated the higher coating efficiency of 50:50 BMSL on the gluten which led to the least values in OS, LW, LV and SV. Same colour variations reflected also on the inside of the loaves (Figure 3f) which is an indication that CCC is a function of BM. Their CCC gradually changed from light-brown to dark brown compared to control’s lighter colour. The variations could be due to Maillard browning resulting from higher BM protein content (Table 2) which may have reacted with dough carbohydrate during baking. Also, caramelization may have contributed too. Generally, surface colour depends both on the physicochemical characteristics of the raw dough (water content, pH, reducing sugars and amino acid content). And the baking temperaturetime regime, air speed, relative humidity and mode of heat transfer. Besides, solute transfer rate (controlled by gluten network) from inside the loaves to their surfaces decides crust thickness. This could explain the reason for decreasing LV trend compared to increasing crumb and crust colour. Therefore, BM correlated positively with bread crust thickness.

Figure 3: (a) 100% margarine; (b) 80/20; (c) 50/50; (d) 20/80;(e) 100% BM; (f) Transverse sections.

Sensory characteristics

Appearance: Appearance is one of the sensory attributes prerequisite for acceptability as the consumers first appreciate with their eyes before accepting or rejecting the product. Table 6 depicts the sensory scores of BMSBs by the panelists. The control was rated (7.56) slightly higher than 100% BM bread sample (7.45). The increase (7.10-7.35) in BMSBs with BMSL increase which peaked at 20% margarine and 80% BM blend could primarily be ascribed to Maillard browning between the BM protein and flour carbohydrate. This harmonized with the crumb and crust colour trend (Fig 3a-f). Increasing the substitution levels beyond the levels used in this study may likely improve the appearance depending on choice.

| Samples | Appearance | Taste | Texture | Aroma | Overall acceptability |

| A | 7.56a ± 0.69 | 7.75a ± 1.02 | 6.80a ± 1.64 | 7.05a ± 1.32 | 8.05a ± 0.76 |

| B | 7.10a ± 1.17 | 7.05a ± 1.57 | 7.25a ± 1.65 | 7.10a ± 1.77 | 7.70ab ± 1.08 |

| C | 7.10a ± 1.45 | 7.00a ± 1.65 | 6.90a ± 1.83 | 6.75a ± 1.59 | 7.15b ± 0.99 |

| D | 7.35a ± 1.35 | 7.25a ± 1.41 | 6.95a ± 1.28 | 6.75a ± 1.33 | 7.25ab ± 1.16 |

| E | 7.45a ± 1.15 | 7.15a ± 1.60 | 6.55a ± 1.88 | 6.85a ± 1.79 | 7.25ab ± 1.97 |

| Note: Values are means of triplicate determination ± standard deviation. Values in the same column with different superscript are significantly (p<0.05) different. A=Bread made with 100% margarine (control). B=Bread made with 80% margarine and 20% bone marrow. C=Bread made with 50% margarine and 50% bone marrow. D=Bread made with 20% margarine and 80% bone marrow. E=Bread made with 100% bone marrow. | |||||

Table 6: Effects of bone marrow substitution on the acceptability levels of the bread samples.

Taste: Same increase as in appearance was observed without significant (p>0.05) variation except that the 50:50 BM bread had the least value (7.00). The increase could be underlined by fat increase (BM) which increases flavour retention. Both BMSBs (7.00-7.25) and 100% BM bread (7.15) samples had nice tastes but are slightly (p>0.05) lower than the control (7.75). These could spell slight influence of BMSL on the breads. Provided it does not affect other bread parameters up to the point of total rejection, the taste of the BMSBs could be improved beyond the control by increasing the BMSL used in this study.

Texture: The texture of the control (6.80) was rated slightly (P>0.05) higher than 100% BM substituted sample (6.55) by the panelists. This justified the slight textural decrease (7.25-6.90) of the entire BMSBs, but higher than the control unlike 100% BM bread. The decrease was more in 50:50 BMS level indicating least contribution to bread texture. The slight textural improvement compared to the control could be traced to fat increase (from BM) which decreases dough gas retention that enhances the loaf volume to the desirable texture of the panelists [10]. These are indications that BM substitution had no noticeable effects on the bread texture as there were no significant (p>0.05) variation between the entire bread samples. Despite these, maximum texture is achievable at not more than 20% BMSL. This also aligned with similarity of the internal bread structure and the panelists’ ratings.

Aroma: The BMSL had slight impart on the bread aroma as there was no significant (p>0.05) variations in the entire bread samples. Despite this, the aroma rating of the control (7.05) was slightly higher than that of the 100% BM bread sample (6.85) which invariably could be the reason why the aroma scores of the BMSBs decreased (7.10-6.75) with increase in the BMSL lower than the control and 100% BM bread sample. The aroma peaked (7.10) at 20% BMSL more than the control (7.05) indicated 20% maximum substitution level like in the texture.

Overall acceptability: There was no significant (p>0.05) acceptability variation scores of the entire BMSBs (7.25-7.70) and 100% BM bread (7.25) except in the equal blend sample which had the least score (7.15). Any sample that has highest score in most of the attributes than the rest is the most accepted. The control with slight (p>0.05) higher scores in appearance and taste as well as second in aroma than the rest sample was liked very much (8.05) followed by the 20% BMSB. The rest bread samples were liked moderately indicating close correlation. Positive correlation of acceptability with BM indicated linear increase with BMSL increase.

Conclusion

The study indicated that substitution of margarine with bone marrow in bread production is feasible with physical and nutritional benefits, and should be encouraged. Most bread samples improved in their indexes in response to increase in bone marrow substitution levels with peak at 20%. Fat, energy, protein, vitamins and mineral levels improved significantly (p<0.05) in the bone marrow substituted breads and should be considered as a functional bread considering their health benefits. Acceptability of the entire bread samples never differed significantly except in the 100% margarine and 50% bone marrow substituted breads. The 20% bone marrow substitution level and 100% wheat breads were liked very much while the rest were liked moderately.

Acknowledgements

The authors are grateful to the Department of Food Science and Technology, Michael Okpara University of Agriculture, Umudike for providing Laboratory space and equipment for the analysis.

Conflict of Interest

The authors declared no conflict of interest.

Funding Sourcing

There was no funding from any person or organization.

References

- Adeyeye EI (2014) Bone marrow: A source of nutritionally valuable fats as typified in the femur of ram and bull. OJACR 2: 1-5

- Albarracin W, Sanchez IC, Grau R, Barat JM (2011) Salt in food processing; usage and reduction: A review. Int J Food Sci 46:1329-1336

- Alinnor IJ, Oze R (2011) Chemical evaluation of the nutritive value of Pentaclethra macrophylla benth (African Oil Bean) seeds. Pak J Nutr 10:355-359

- AOAC (2010) Official method of analysis. 19th edition, Washington, DC, USA.

- Avila Rodriguez MI, Rodriguez Barroso LG, Sanchez ML (2018) Collagen: A review on its sources and potential cosmetic applications. J Cosmet Dermatol 17:20-26

[Crossref] [Google Scholar] [PubMed]

- Alao BO, Falowo AB, Chulayo A, Muchenje V (2017) The potential of animal by-products in food systems: Production, prospects and challenges. Sustainability 9:1089

- Barak S, Mudgil D, Khatkar BS (2014) Influence of gliadin and glutenin fractions on rheological, pasting, and textural properties of dough. Int J Food Prop 17:1428-1438

[Crossref]

- Barak S, Mudgil D, Khatkar BS (2013) Relationship of gliadin and glutenin proteins with dough rheology, flour pasting and bread making performance of wheat varieties. LWT Food Sci Technol 51:211-217

- Buehler BA (2011) Vitamin B2: Riboflavin. Evid Based Complement Alternat Med 16: 88-90

- Colla K, Costanzo A, Gamlath S (2018) Fat replacers in baked food products. Foods 7:192

[Crossref] [Google Scholar] [PubMed]

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences